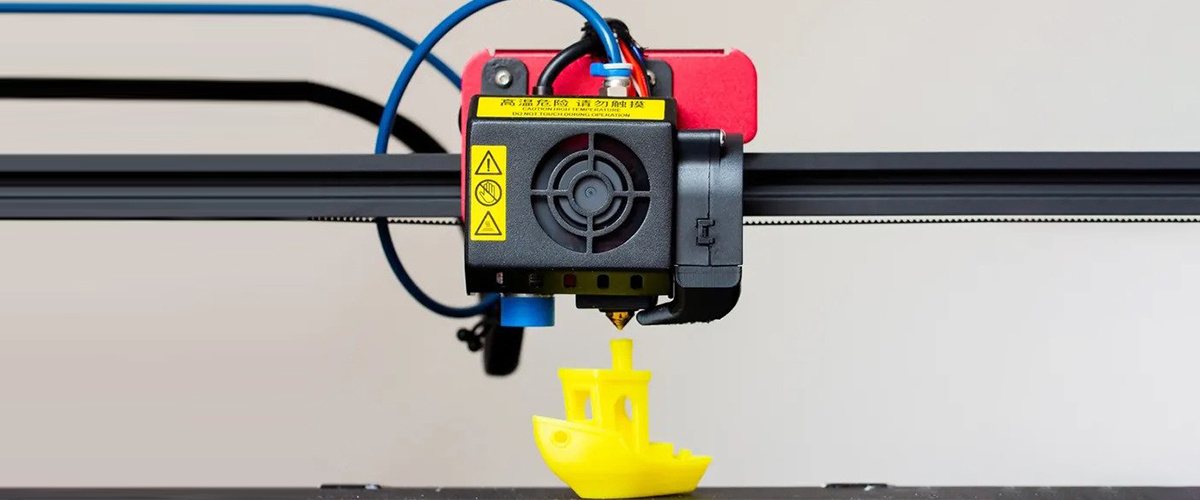

Use of 3D printing is prevalent in various industry verticals. 3D printing is setting new norms in the area of product design and product manufacturing. With 3D printing, you can create prototypes as well as machine components in an accurate and easier way.

13 application of 3D printing in diverse sectors

3D printing refers to the process of bringing a 3D object, which is in CAD (Computer-aided Design) form, into its physical form through successive addition of printing material in various layers. You are not required to use presses, molds, machine tools, hammers, casting materials, etc. to manufacture the product. The file format for 3D printing is STL. Let us see the applications of 3D printing in various industries.

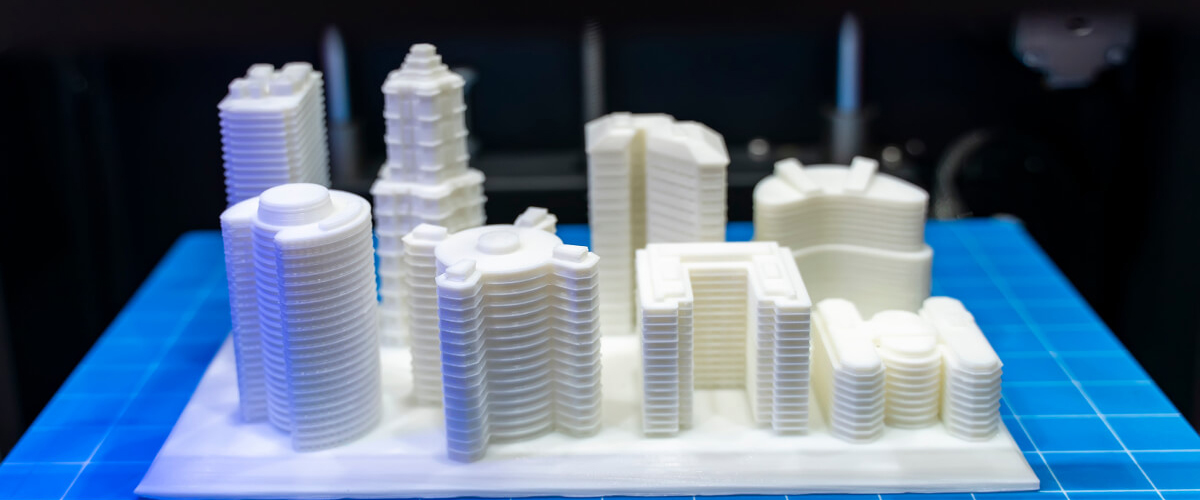

3D Printing in Architecture

-

Preparing Study Models

You can get white architectural models printed in desired formats. This helps you to present your project related ideas in the initial stages in a realistic manner.

-

Developing Competition Models

You can get models of houses or concrete structures created through 3D printing. Monochromatic models, which are as big as 27”, can be printed in one-go. Larger models can be sectioned carefully before printing. This will allow you to showcase your ideas in a more detailed way.

-

Building Promotional Scale Models

You can get 3D plans, scale models, or cutaways printed realistically for use in trade shows, promotional events, showrooms etc. This assists your potential clients to visualize the work clearly.

3D Printing in Medical Domain

-

Developing Customized Medical Devices and Products

You can get tailored medical devices printed within a short span of time. Prosthetics, hearing aids, etc. can be manufactured as per specific needs of patients. Even small clinics can get implants created through 3D printing. Healthcare practitioners can make use of 3D print ready files in an optimal manner in order to create custom prototypes.

-

Training Prospective Surgeons

3D replicas of body parts help in offering insights into the human anatomy and the intricacies of surgery to medical students who get trained in surgery. 3D medical databank of patient imagery can be used for printing anatomical parts for educational purposes.

-

Improving Supply Chain Efficiency

You can maintain an online databank of 3D models. This would keep the models accessible from any part of the world and would allow distributors to print parts on demand.

3D Printing in the Chemical Industry

You can maintain an online databank of 3D models. This would keep the models accessible from any part of the world and would allow distributors to print parts on demand.

-

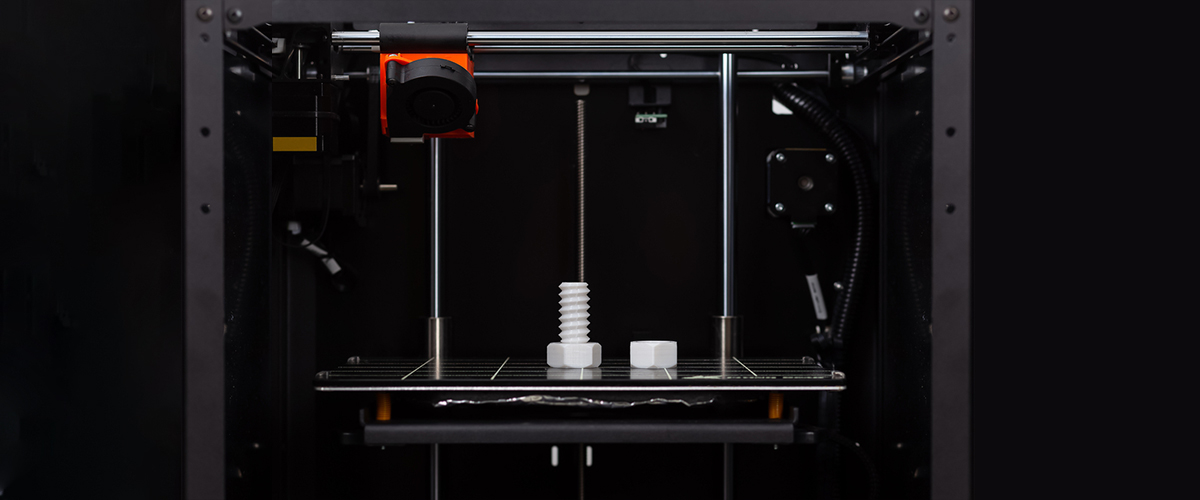

Getting Machine Parts Printed

You can get complex machine parts 3D printed. 3D designs of prototypes help reduce inventory and facilitate faster printing of products at lower costs. Many complex tools which are difficult to manufacture using conventional methods can be affordably printed. A special type of plastic offers the flexibility to mold tools accurately in the way you want. High 3D print resolutions extending up to 100 microns guarantee accuracy.

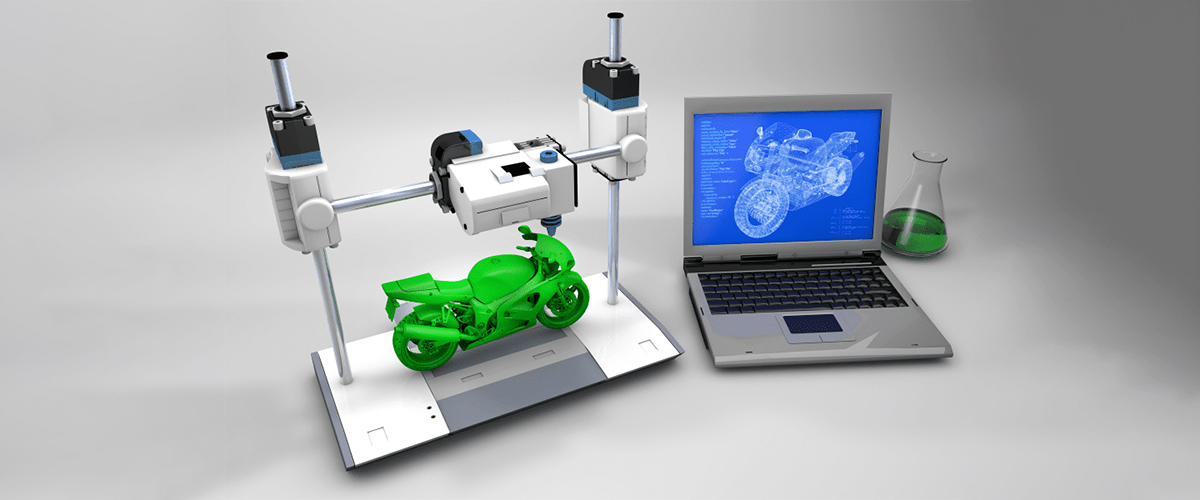

3D Printing in Mechanical Engineering

You can maintain an online databank of 3D models. This would keep the models accessible from any part of the world and would allow distributors to print parts on demand.

-

Optimizing Topology

Complex mechanical designs that are hard to manufacture with traditional means can be developed easily with 3D printers. You can optimize the product topology to perfectly balance its weight and endurance with the printing costs.

-

Reducing Assembly Time

You can batch produce machine parts consisting of different components. This minimizes assembling and welding needs, which would otherwise cause weakness or impurities. This, in turn, leads to the development of stronger machine features.

-

Streamlining Supply Chain

With a few 3D models, you can get numerous mechanical components manufactured quickly. There is no need to maintain a stock of parts. Based on demand, you can print parts at optimized costs.

3D Printing in Food Industry

-

Calibrating Food Processing Tools

To get your food processing machines calibrated, you can use 3D print food replicas with them. 3D printing of plastic foods for a number of times would help in testing the efficacy of your equipment.

-

Manufacturing Complex Processing Equipment

Complex parts used in food processors can be 3D printed. Complicated geometries of instruments can be produced at optimized costs.

-

Building Prototypes

You can build various prototypes from drawings to analyze if improvements are needed in machines or to implement your innovative ideas in food-related consumer products. You can validate the ideas evolved during research very easily. Product layouts can be tested at minimal costs.

3D Printing in Education Sector

-

Enriching the Learning Process

You can get complex ideas from lessons printed to make it easier for learners to understand the concept. Ideas can be physically tinkered with by students.

-

Creating Lifelike Project-Outcomes

With desktop 3D printer, you can allow students to develop prototypes of their projects with different materials and finishes in cost competitive manner.

-

Facilitating Learning in the Engineering Education Industry

Engineering students can simulate real-life mechanical components or prototypes. This practical approach to learning would promote critical thinking in learners.

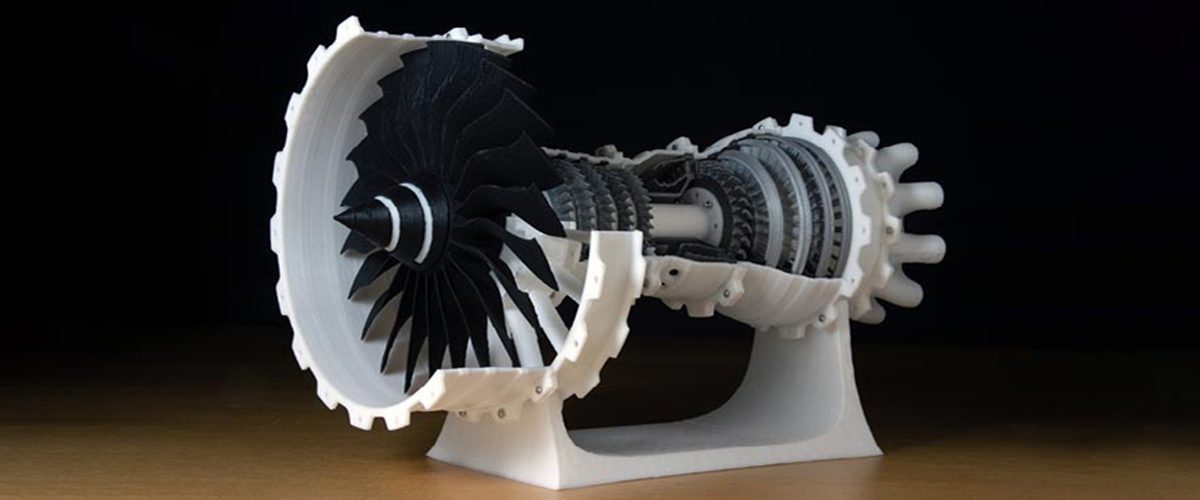

3D Printing in Aeronautical Domain

-

Getting Your Design Optimized

3D printing offers an advantage over traditional injection molding and CNC machining. You can materialize any innovative idea involving complex geometry. Product will be lightweight. Assembly time can be reduced as fixtures and jigs can be inserted right in 3D model before printing.

-

Reducing Costs

In aeronautics segment, price of tools is high and production volume is low. This causes the amortization cost to go up. With 3D printing, you need not make a mold and can print out products whenever needed at minimal cost.

-

Enjoying Rapid Prototyping

You can avail of rapid prototyping with flexibility in design, zero molding tools and cost efficiency. As assembling needs are minimized with integrated design, your time is saved

3D Printing for Drones

-

Getting Drone Parts Printed

You can use 3D printers for building prototypes and manufacturing drone parts quickly. You can add the lightweight feature by optimizing the topology of the structure. This will improve battery life, help you customize components and print parts that are difficult to find.

-

Prolonging the Life of Drones

You can build replicas of different types of drones such as pocket, racing, and quadcopter drones and their parts including frames, go-pro and camera mount, landing gear etc. using materials that are lighter in weight.

-

On the professional front, you can use drones for surveying, surveillance, cinematography for aerial vision, topography-analysis, imaging etc. You can now produce drones at much lesser costs.

3D Printing for Retail Segment

-

Manufacturing Any Type of Product

You can use 3D printing to create diversely-colored products out of resin, plastic or other materials. You can also create clothes through 3D printing. Print customization allows you to adopt an innovative approach for meeting your customers’ needs. You can create unique products or assimilate 3D printed things in the product using any 3D print design software. Catalogs can be created with 3D printed products.

3D Printing in the Automotive Segment

-

Developing Prototypes Easily

Rapid prototyping consumes lesser time compared to what traditional methods such as injection molding would take. You can quicken product development and make improvements in product through multiple iterations. The production cost is also reduced.

-

Making Improvements to Object Designs

You can print creative and complex geometries easily. The costs of prototype as well as the final product can be reduced. Lattices make products lightweight. You can reduce the assembling time by inserting fixtures and jigs in components very easily.

-

Preparing Models for Demonstrations

You can do the needful customization and create exact replicas of products on sale for demonstration. Once you receive orders, you can start production. You can prepare models of racing cars to lure your prospective customers. You need not maintain a huge inventory of spares. Have 3D files ready and print out the components on requirement basis.

3D Printing for Fashion

-

Innovatating with Textiles

You can use newer materials to create unique designs. You can reinterpret any classic design with 3D printed textiles. You can make slinky clothing in a customized manner using rigid as well as flexible plastic options.

3D Printing for Industrial Goods

-

Printing Parts Easily and Quickly

You can print concept models, components, and objects having complex designs quickly. You can employ rapid prototyping for improving accuracy and the time to market products.

-

Getting Your Machine’s Performance Optimized

You can print complex geometries. Also, creating lightweight and robust parts prolongs a product’s lifecycle. If a critical part gets broken, you need not replace the entire machine. After designing the 3D part, you can get it printed. You can re-engineer the fragile parts to improve their longevity. If a part has become obsolete, you can replace it with a new part easily.

3D Printing for Broadcasting

-

Print Replicas of Movie Stars

You can bank on the passion that fans have for their favorite movie stars by selling them replicas of popular cine stars. You can add personal touches to your marketing approaches.

-

Get Props for Show Printed

You can get the props needed for any televised show printed in 3D. Since most of the props will be used once, you can 3D print them quickly and inexpensively. For electronics, you can print customized circuit boards.

Conclusion

By now, you must have become familiar with the benefits of 3D printing in different industries and have identified how you can capitalize on 3D printing in your area. There are several professional 3D design services companies offering 3D print-ready models at competitive prices and all you need to do is to identify the right partner that would guarantee you the delivery of high-quality 3D prints at reasonable rates and within predetermined deadlines.