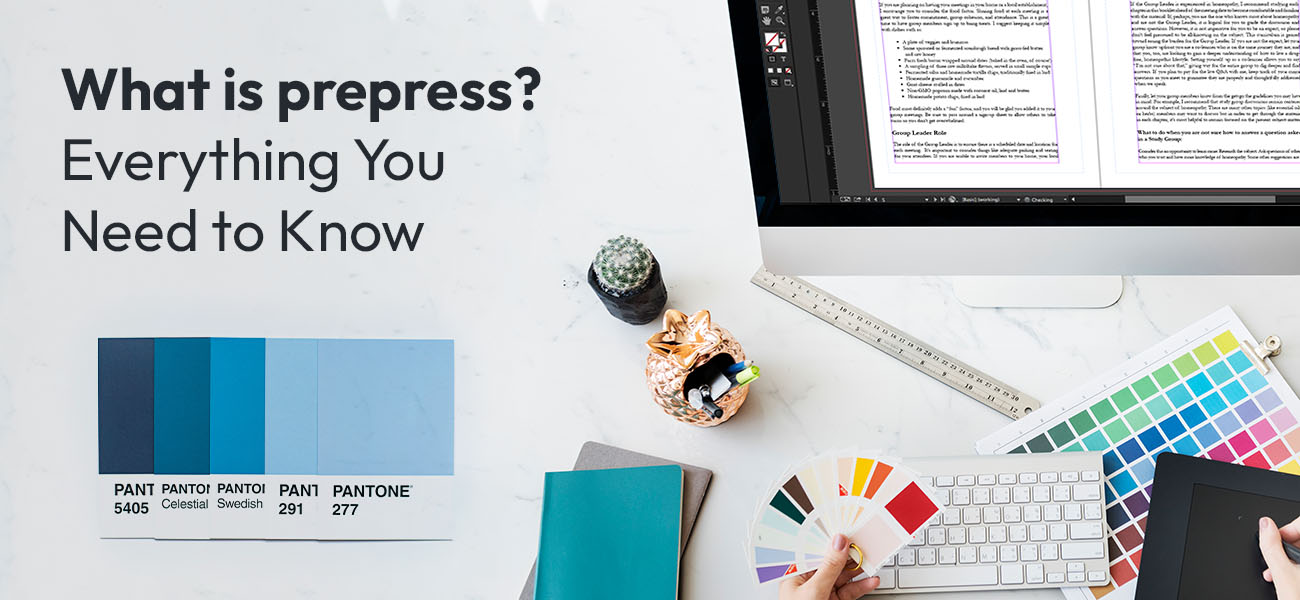

We often get engrossed in brochures, magazines, or any printable manuals for their texture, design, packaging, and more. Have you ever thought about what makes us do so? It is because that particular packaging design needs to undergo something called prepress. It is one of the important steps in building a sync between the design and printing.

It's where the designers, along with print experts, come together to find out errors, balance the colour, ensuring the final product looks perfect on paper. In this blog, we will understand what is prepress, its importance, and the crucial steps involved in making that perfect design come to life.

What Is Prepress in Printing?

Prepress in printing refers to the preparation of digital files for print production. Before the printing process begins, it guarantees that all layouts, text, and visual components are correct. In order to achieve accurate and reliable print results, the prepress process usually includes design validation, color correction, image optimization, typing, and proofreading.

Designers and technicians usually check the colour profiles(CMYK), file formats, and image resolution during the prepress workflow, ensuring compatibility with printing equipment. It acts as a bridge between the creative design team and physical printing, minimizing material waste or reprints.

File preparation, layout adjustments, soft or hard proofing along with final approval before it goes for print are included as a part of the stages of prepress, which ensures accuracy and consistency. It plays a vital role maintaining print quality and efficiency throughout the production line.

The Prepress Process: Step-by-Step Overview

-

Step 1 - Design and Layout Preparation

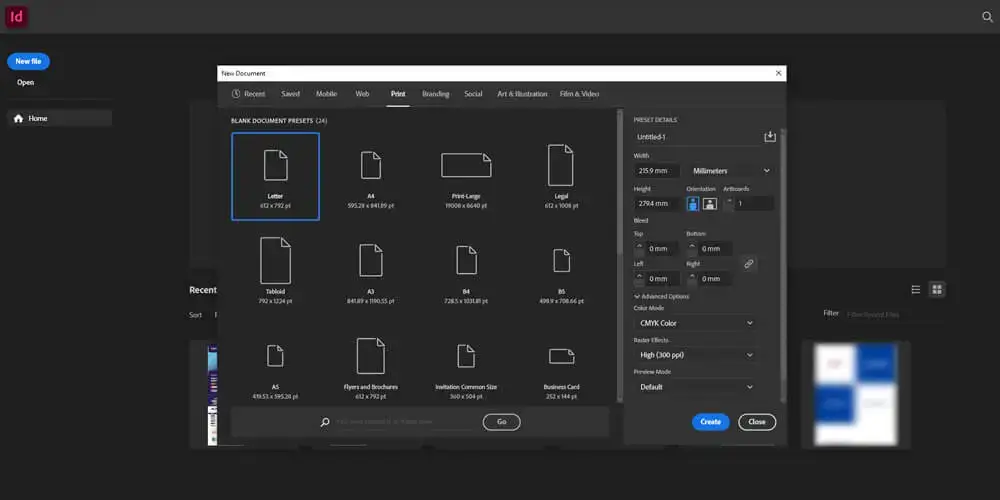

The first and foremost stage of prepress starts with preparing for design and layout. You can say that the foundational alignment starts from here. This is where every detail, text, and visual element is monitored for maintaining printing accuracy.

In this stage, designers ensure that the files have the correct page size, bleeding areas, and margins to avoid mistakes while cropping. It also includes the correct adjustment of colors, text, and images to have that professional outlook.

Popular tools like Adobe InDesign, Illustrator, and CorelDRAW are used for creating layout compatibility with printing presses. Once the layout seems ready, files are saved in print-ready formats, for instance, PDF/X, maintaining font and color consistency.

-

Step 2 - Copy Editing and Proofreading

The next step is to ensure the content is copyedited and proofread prior to production. Within this step, it matters if the content adheres to the established rules of grammar, spelling, punctuation, and formatting.

Editors will have to edit for accuracy, clarity, tone, and style in both body text and captions. Use of soft-proofing tools, like Adobe Acrobat Pro, or other online proofreading platforms like Grammarly, Hemingway Editor, QuillBot, Scribendi, Scribbr, etc. also allows for collaboration in real-time review and error detection prior to final sign-off.

-

Step 3 - Image Correction and Color Management

This is the third step that ensures all the images are optimized for print. Here, print professionals tend to adjust brightness, sharpness, and contrast, and will perform color correction for matching the desired output.

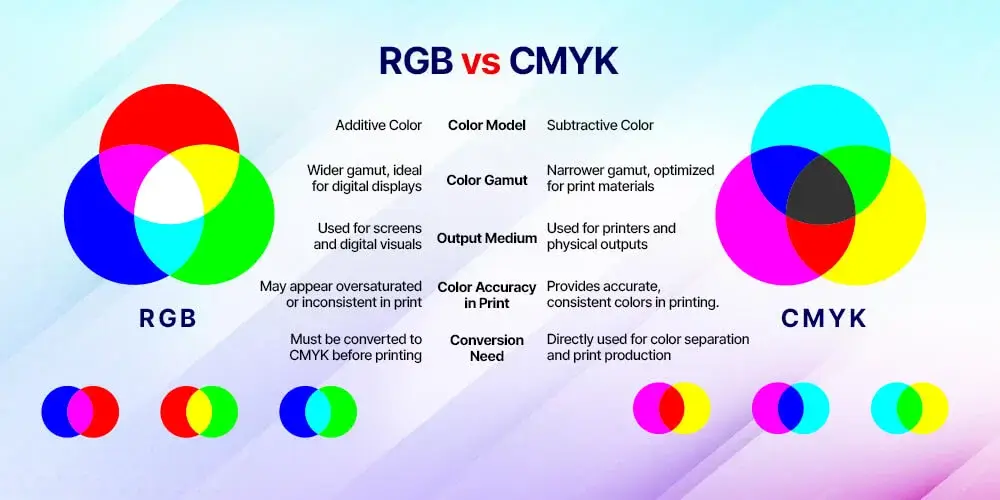

After that, the images from RGB (used to screen) are converted to CMYK (used for printing) to ensure accurate dye. Tools such as Adobe Photoshop and CMG Colorserver can help standardize color profiles across different printers. In addition, the right color control ensures that printed materials look similar on the screen and in physical shape.

RGB vs CMYK Comparison for Print Accuracy

Factor RGB CMYK Color Model Additive color model using light (Red,Green, Blue) Subtractive color model using inks (Cyan, Magenta, Yellow, Black). Color Gamut Wider gamut, ideal for digital displays. Narrower gamut, optimized for print materials. Output Medium Used for screens and digital visuals. Used for printers and physical outputs. Color Accuracy in Print May appear oversaturated or inconsistent in print. Provides accurate, consistent colors in printing. Conversion Need Must be converted to CMYK before printing. Directly used for color separation and print production. -

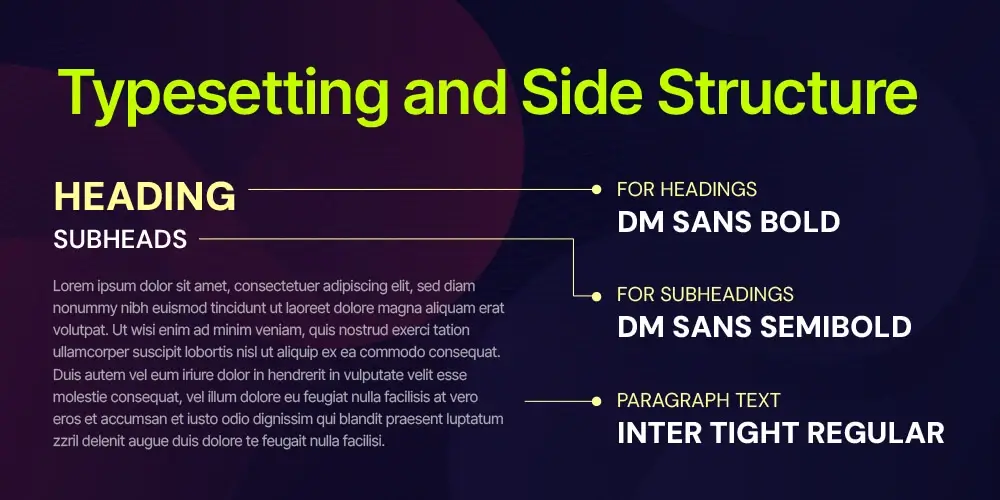

Step 4 -Typesetting and Side Structure

In this step, typesetting ensures that the text is properly adjusted, readable and visually balanced. Designers focus on font selection, cutting, leading and text current on pages. Consistency in font size, style and distance helps maintain a professional appearance. Side structure integrates harmonic images, text and design elements, and ensures that each side follows the same visual hierarchy and brand standards.

-

Step 5 - Proofing and Approval

Before final printing, both digital and hard proofs are prepared to confirm color authority, layout adjustments, and image sharpness. Digital proofing is all about instant screen previews, while on the other hand, hard proofing tends to drive the print on actual paper. Furthermore, preflight checks are performed using tools like Adobe Acrobat for identifying problems like missing fonts or incorrect profiles. Post consideration, upon client approval, the file then moves to the production stage.

-

Step 6 - Plate Making and Final Output

In the final prepress stage, the approved digital files are converted to printing plates using CTP (computer-to-plate) technology. This process eliminates film-based intermediate products and ensures rapid exchanges and high accuracy. Each plate represents one of four process colors: cyan, magenta, yellow, and black (CMYK), which together produce a full-color pressure. After calibration and adjustment, the plates are mounted on a pressure press that is ready for mass production.

Importance of Prepress in Printing

The prepress plays an important role in determining the general quality and cost-effectiveness of any print job. It acts as the foundation where each design element - text, image, and layout - is refined and prepared for precise printing. A well-executed prepress process ensures that the final output looks accurate as intended and reduces errors that can lead to costly imprints or material waste.

This step includes checking file formats, ensuring proper resolution, managing color profiles, and confirming bleeding and margins. Each of these steps helps eliminate discrepancies that can be displayed in the press. Even a minor color match or adjustment error can, for example, affect the professionalism of the final pressure, especially in marketing materials such as brochures or packaging.

Color Fidelity is another great advantage of proper prepress work. Through precise color calibration and proofread, printers can maintain the texture between the digital evidence and the actual printed product. This accuracy level not only improves visual appeal but also strengthens brand identity by ensuring uniform colors across all materials.

In short, Prepress is a calm but crucial step that connects creativity and production - saves time, money, and ensures that each printed piece meets the highest standards for accuracy and quality.

Prepress vs Press vs Post-Press

| Aspect | Prepress | Press | Post-Press |

|---|---|---|---|

| Purpose | Prepares files and layouts for printing | Involves actual printing on paper or material | Handles finishing and packaging of printed items |

| Key Activities | Design setup, proofing, color correction, imposition | Ink application, plate setup, and print run | Cutting, folding, binding, laminating, or embossing |

| Tools Used | Adobe InDesign, Illustrator, RIP software | Offset press, digital press, inkjet printers | Guillotine cutters, binders, laminators |

| Quality Focus | Ensures accurate colors, layout, and image resolution | Controls ink density and print consistency | Maintains precision in finishing and presentation |

| Output | Print-ready digital files | Printed sheets or materials | Finished, ready-to-distribute printed products |

Common Prepress Mistakes and How to Avoid Them

- Lack of bleeding or crop marks: Right bleeding, along with crop marks, is important for ensuring accurate trimming after printing.

- Low-resolution images: It's important to make use of images of at least 300 dpi for maintaining sharpness and clarity in prints.

- Wrong color profile: It's important to convert all files to CMYK before printing for ensuring color authority and texture.

- Font posting problems: Post or emphasize fonts to prevent text from changing or disappearing during printing.

- Skipped preflight checks: Always perform a final preflight check to match the layout, color, or file error before the press step.

Conclusion

In short, understanding what is Prepress helps companies to understand how important it is to achieve flawless print results. The prepress process ensures that each file, color, and layout is fully ready before the print begins, saving both time and resources. Accuracy at this level prevents costly prints and maintains branding consistency.

For companies that want accuracy and reliability, professional prepress services are crucial. MAPSystems provides end-to-end prepress solutions from file layout to proof and ensures that each project meets the highest print standards. Partner with us to make your print production seamless, efficient, and flawless.

Frequently Asked Questions

Prepress includes steps such as design setup, text editing, image correction, typing, proofreading, and plate production - all done to prepare files for printing completely.

Prepress is important because it helps eliminate design or color errors and ensures that the final printed material accurately matches the digital version and maintains high print quality.

Preflight is a quality control process that ensures that all design files, images, fonts, and colors are properly set up and print-ready before the actual print begins.